Application

A laser diode, (LD), injection laser diode (ILD), or diode laser is a semiconductor device similar to a light-emitting diode in which the laser beam is created at the diode's junction.[1] Laser diodes are the most common type of lasers produced, with a wide range of uses that include fiber optic communications, barcode readers, laser pointers, CD/DVD/Blu-ray disc reading/recording, laser printing, laser scanning and light beam illumination.

source by wikipedia

Semi-conductor lasers typical wavelength (660 nm, 635 nm, 532 nm, 520 nm, 445 nm, 405 nm)

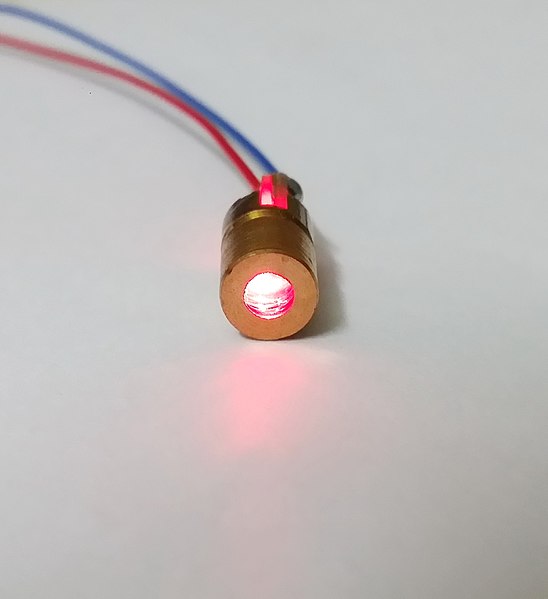

A simple and low power metal enclosed laser diode

Uses:

Laser diodes are numerically the most common laser type, with 2004 sales of approximately 733 million units,[8] as compared to 131,000 of other types of lasers.[9]

Laser diodes find wide use in telecommunication as easily modulated and easily coupled light sources for fiber optics communication. They are used in various measuring instruments, such as rangefinders. Another common use is in barcode readers. Visible lasers, typically red but later also green, are common as laser pointers. Both low and high-power diodes are used extensively in the printing industry both as light sources for scanning (input) of images and for very high-speed and high-resolution printing plate (output) manufacturing. Infrared and red laser diodes are common in CD players, CD-ROMs and DVDtechnology. Violet lasers are used in HD DVD and Blu-ray technology. Diode lasers have also found many applications in laser absorption spectrometry (LAS) for high-speed, low-cost assessment or monitoring of the concentration of various species in gas phase. High-power laser diodes are used in industrial applications such as heat treating, cladding, seam welding and for pumping other lasers, such as diode-pumped solid-state lasers.

Uses of laser diodes can be categorized in various ways. Most applications could be served by larger solid-state lasers or optical parametric oscillators, but the low cost of mass-produced diode lasers makes them essential for mass-market applications. Diode lasers can be used in a great many fields; since light has many different properties (power, wavelength, spectral and beam quality, polarization, etc.) it is useful to classify applications by these basic properties.

Many applications of diode lasers primarily make use of the "directed energy" property of an optical beam. In this category, one might include the laser printers, barcode readers, image scanning, illuminators, designators, optical data recording, combustion ignition, laser surgery, industrial sorting, industrial machining, and directed energy weaponry. Some of these applications are well-established while others are emerging.

Laser medicine: medicine and especially dentistry have found many new uses for diode lasers.[10][11][12][13] The shrinking size and cost[14] of the units and their increasing user friendliness makes them very attractive to clinicians for minor soft tissue procedures. Diode wavelengths range from 810 to 1,100 nm, are poorly absorbed by soft tissue, and are not used for cutting or ablation.[15][16][17][18] Soft tissue is not cut by the laser’s beam, but is instead cut by contact with a hot charred glass tip.[17][18] The laser’s irradiation is highly absorbed at the distal end of the tip and heats it up to 500 °C to 900 °C.[17]Because the tip is so hot, it can be used to cut soft-tissue and can cause hemostasis through cauterization and carbonization.[17][18] Diode lasers when used on soft tissue can cause extensive collateral thermal damage to surrounding tissue.[17][18]

Uses which may make use of the coherence of diode-laser-generated light include interferometric distance measurement, holography, coherent communications, and coherent control of chemical reactions.

Uses which may make use of "narrow spectral" properties of diode lasers include range-finding, telecommunications, infra-red countermeasures, spectroscopic sensing, generation of radio-frequency or terahertz waves, atomic clock state preparation, quantum key cryptography, frequency doubling and conversion, water purification (in the UV), and photodynamic therapy (where a particular wavelength of light would cause a substance such as porphyrin to become chemically active as an anti-cancer agent only where the tissue is illuminated by light).

Uses where the desired quality of laser diodes is their ability to generate ultra-short pulses of light by the technique known as "mode-locking" include clock distribution for high-performance integrated circuits, high-peak-power sources for laser-induced breakdown spectroscopy sensing, arbitrary waveform generation for radio-frequency waves, photonic sampling for analog-to-digital conversion, and optical code-division-multiple-access systems for secure communication.

Common wavelengths

Visible light

- 405 nm – InGaN blue-violet laser, in Blu-ray Disc and HD DVD drives

- 445–465 nm – InGaN blue laser multimode diode recently introduced (2010) for use in mercury-free high-brightness data projectors

- 510–525 nm – Green diodes recently (2010) developed by Nichia and OSRAM for laser projectors.

- 635 nm – AlGaInP better red laser pointers, same power subjectively twice as bright as 650 nm

- 650–660 nm – GaInP/AlGaInP CD and DVD drives, cheap red laser pointers

- 670 nm – AlGaInP bar code readers, first diode laser pointers (now obsolete, replaced by brighter 650 nm and 671 nm DPSS)

Infrared

- 760 nm – AlGaInP gas sensing: O2

- 785 nm – GaAlAs Compact Disc drives

- 808 nm – GaAlAs pumps in DPSS Nd:YAG lasers (e.g., in green laser pointers or as arrays in higher-powered lasers)

- 848 nm – laser mice

- 980 nm – InGaAs pump for optical amplifiers, for Yb:YAG DPSS lasers

- 1,064 nm – AlGaAs fiber-optic communication, DPSS laser pump frequency

- 1,310 nm – InGaAsP, InGaAsN fiber-optic communication

- 1,480 nm – InGaAsP pump for optical amplifiers

- 1,512 nm – InGaAsP gas sensing: NH3

- 1,550 nm – InGaAsP, InGaAsNSb fiber-optic communication

- 1,625 nm – InGaAsP fiber-optic communication, service channel

- 1,654 nm – InGaAsP gas sensing: CH4

- 1,877 nm – GaInAsSb gas sensing: H2O

- 2,004 nm – GaInAsSb gas sensing: CO2

- 2,330 nm – GaInAsSb gas sensing: CO

- 2,680 nm – GaInAsSb gas sensing: CO2

- 3,030 nm – GaInAsSb gas sensing: C2H2

- 3,330 nm – GaInAsSb gas sensing: CH4

List of laser applications

source by wikipedia

Many scientific, military, medical and commercial laser applications have been developed since the invention of the laser in 1958. The coherency, high monochromaticity, and ability to reach extremely high powers are all properties which allow for these specialized applications.

Scientific

In science, lasers are used in many ways, including:

- A wide variety of interferometric techniques

- Raman spectroscopy

- Laser induced breakdown spectroscopy

- Atmospheric remote sensing

- Investigating nonlinear optics phenomena

- Holographic techniques employing lasers also contribute to a number of measurement techniques.

- Laser based lidar (LIght raDAR) technology has application in geology, seismology, remote sensing and atmospheric physics.

- Lasers have been used aboard spacecraft such as in the Cassini-Huygens mission.

- In astronomy, lasers have been used to create artificial laser guide stars, used as reference objects for adaptive optics telescopes.

Lasers may also be indirectly used in spectroscopy as a micro-sampling system, a technique termed Laser ablation (LA), which is typically applied to ICP-MS apparatus resulting in the powerful LA-ICP-MS.

The principles of laser spectroscopy are discussed by Demtröder.[1]

Spectroscopy

Most types of laser are an inherently pure source of light; they emit near-monochromatic light with a very well defined range of wavelengths. By careful design of the laser components, the purity of the laser light (measured as the "linewidth") can be improved more than the purity of any other light source. This makes the laser a very useful source for spectroscopy. The high intensity of light that can be achieved in a small, well collimated beam can also be used to induce a nonlinear optical effect in a sample, which makes techniques such as Raman spectroscopy possible. Other spectroscopic techniques based on lasers can be used to make extremely sensitive detectors of various molecules, able to measure molecular concentrations in the parts-per-1012 (ppt) level. Due to the high power densities achievable by lasers, beam-induced atomic emission is possible: this technique is termed Laser induced breakdown spectroscopy (LIBS).

Heat Treatment

Heat treating with lasers allows selective surface hardening against wear with little or no distortion of the component. Because this eliminates much part reworking that is currently done, the laser system's capital cost is recovered in a short time. An inert, absorbent coating for laser heat treatment has also been developed that eliminates the fumes generated by conventional paint coatings during the heat-treating process with CO2 laser beams.

One consideration crucial to the success of a heat treatment operation is control of the laser beam irradiance on the part surface. The optimal irradiance distribution is driven by the thermodynamics of the laser-material interaction and by the part geometry.

Typically, irradiances between 500-5000 W/cm^2 satisfy the thermodynamic constraints and allow the rapid surface heating and minimal total heat input required. For general heat treatment, a uniform square or rectangular beam is one of the best options. For some special applications or applications where the heat treatment is done on an edge or corner of the part, it may be better to have the irradiance decrease near the edge to prevent melting.

Lunar laser ranging

When the Apollo astronauts visited the moon, they planted retroreflector arrays to make possible the Lunar Laser Ranging Experiment. Laser beams are focused through large telescopes on Earth aimed toward the arrays, and the time taken for the beam to be reflected back to Earth measured to determine the distance between the Earth and Moon with high accuracy.

Photochemistry

Some laser systems, through the process of mode locking, can produce extremely brief pulses of light - as short as picoseconds or femtoseconds (10−12 - 10−15 seconds). Such pulses can be used to initiate and analyze chemical reactions, a technique known as photochemistry. The short pulses can be used to probe the process of the reaction at a very high temporal resolution, allowing the detection of short-lived intermediate molecules. This method is particularly useful in biochemistry, where it is used to analyse details of protein folding and function.

Laser scanner

Laser barcode scanners are ideal for applications that require high speed reading of linear codes or stacked symbols.

Laser cooling

A technique that has recent success is laser cooling. This involves atom trapping, a method where a number of atoms are confined in a specially shaped arrangement of electric and magnetic fields. Shining particular wavelengths of light at the ions or atoms slows them down, thus cooling them. As this process is continued, they all are slowed and have the same energy level, forming an unusual arrangement of matter known as a Bose–Einstein condensate.

Nuclear fusion

Some of the world's most powerful and complex arrangements of multiple lasers and optical amplifiers are used to produce extremely high intensity pulses of light of extremely short duration, e.g. laboratory for laser energetics, National Ignition Facility, GEKKO XII, Nike laser, Laser Mégajoule, HiPER. These pulses are arranged such that they impact pellets of tritium–deuterium simultaneously from all directions, hoping that the squeezing effect of the impacts will induce atomic fusion in the pellets. This technique, known as "inertial confinement fusion", so far has not been able to achieve "breakeven", that is, so far the fusion reaction generates less power than is used to power the lasers, but research continues.

Microscopy

Confocal laser scanning microscopy and Two-photon excitation microscopy make use of lasers to obtain blur-free images of thick specimens at various depths. Laser capture microdissection use lasers to procure specific cell populations from a tissue section under microscopic visualization.

Additional laser microscopy techniques include harmonic microscopy, four-wave mixing microscopy[2] and interferometric microscopy.[3]

Military

Military uses of lasers include applications such as target designation and ranging, defensive countermeasures, communications and directed energy weapons.

Directly as an energy weapon

Directed energy weapons are being developed, such as Boeing's Airborne Laser which was constructed inside a Boeing 747. Designated the YAL-1, it was intended to kill short- and intermediate-range ballistic missiles in their boost phase.[4]

Another example of direct use of a laser as a defensive weapon was researched for the Strategic Defense Initiative (SDI, nicknamed "Star Wars"), and its successor programs. This project would use ground-based or space-based laser systems to destroy incoming intercontinental ballistic missiles (ICBMs). The practical problems of using and aiming these systems were many; particularly the problem of destroying ICBMs at the most opportune moment, the boost phase just after launch. This would involve directing a laser through a large distance in the atmosphere, which, due to optical scattering and refraction, would bend and distort the laser beam, complicating the aiming of the laser and reducing its efficiency.

Another idea from the SDI project was the nuclear-pumped X-ray laser. This was essentially an orbiting atomic bomb, surrounded by laser media in the form of glass rods; when the bomb exploded, the rods would be bombarded with highly-energetic gamma-ray photons, causing spontaneous and stimulated emission of X-ray photons in the atoms making up the rods. This would lead to optical amplification of the X-ray photons, producing an X-ray laser beam that would be minimally affected by atmospheric distortion and capable of destroying ICBMs in flight. The X-ray laser would be a strictly one-shot device, destroying itself on activation. Some initial tests of this concept were performed with underground nuclear testing; however, the results were not encouraging. Research into this approach to missile defense was discontinued after the SDI program was cancelled.

- Made by Northrop Grumman:

- On March 18, 2009 Northrop Grumman announced that its engineers in Redondo Beach had successfully built and tested an electric laser capable of producing a 100-kilowatt ray of light, powerful enough to destroy cruise missiles, artillery, rockets and mortar rounds.[5] An electric laser is theoretically capable, according to Brian Strickland, manager for the United States Army's Joint High Power Solid State Laser program, of being mounted in an aircraft, ship, or vehicle because it requires much less space for its supporting equipment than a chemical laser.[6]

- On April 6, 2011, the U.S. Navy successfully tested a laser gun, manufactured by Northrop Grumman, that was mounted on the former USS Paul F. Foster, which is currently used as the navy's test ship. When engaged during the test that occurred off the coast of Central California in the Pacific Ocean test range, the laser gun was documented as having "a destructive effect on a high-speed cruising target", said Chief of Naval Research Admiral Nevin Carr.[7]

- Northrop Grumman has announced the availability of a high-energy solid-state laser weapon system that they call FIRESTRIKE, introduced on 13 November 2008. The system is modular, using 15 kW modules that can be combined to provide various levels of power.

- On 19 July 2010 an anti-aircraft laser described as the Laser Close-In Weapon System was unveiled at the Farnborough Airshow.[8]

- Zeus laser weapon Is the first laser and the first energy weapon of any type to be used on a battlefield. It is used for neutralizing mines and unexploded ordnance.

- Area Defense Anti-Munitions (ADAM) Lockheed Martin experimental fiber laser. 10 kilowatt tested against rockets.[9][10]

- Mid-Infrared Advanced Chemical Laser (MIRACL) A U.S. Navy experimental deuterium fluoride laser. Was tested against an Air Force satellite in 1997.

- In 2011, the U.S. Navy began to test the Maritime Laser Demonstrator (MLD), a laser for use aboard its warships.[11][12] By 2013, the Navy was announcing active deployment in 2014.

- Personnel halting and stimulation response rifle (PHaSR) A non-lethal hand-held weapon developed by the United States Air Force [13] Its purpose is to "dazzle" or stun a target. It was developed by U.S. Air Force's Directed Energy Directorate.

- Pulsed Energy Projectile A laser designed for riot control. A laser pulse ablates material causing a shockwave which stuns the targeted individual. Likely truck-mounted.

- Tactical High Energy Laser (THEL) is a weaponized deuterium fluoride laser developed in a joint research project by Israel and the USA. It is designed to shoot down aircraft and missiles. See also National missile defense.

- Beriev A-60 A Soviet/Russian CO2 gas laser mounted on an Ilyushin Il-76MD transport.

- The Russian truck mounted Almaz HEL[14]

- Boeing Laser Avenger Mounted on an AN/TWQ-1 Avenger combat vehicle.

- Airborne Laser, or Advanced Tactical Laser The U.S. Air Force's plan to mount a CO2 gas laser or COIL chemical laser on a modified Boeing 747 to shoot down missiles.[15][16]

- Portable Efficient Laser Testbed (PELT)[17]

- Laser AirCraft CounterMeasures (ACCM)[citation needed]

- Laser Weapon System (LAWS), which is intended to hold off approaching unmanned aerial vehicles and speedboats. Under development by the U.S. Navy. The system, which can burn through steel, reportedly costed $40 million and took six years to develop.[18]

- High Energy Liquid Laser Area Defense System (HELLADS) A counter-RAM aircraft or truck mounted laser under development by General Atomics under a DARPA contract. 150 kilowatt goal. Uses a lasing medium immersed in an index matchedcoolant.

- See also Electrolaser#Examples of electrolasers.

Defensive countermeasures

Defensive countermeasure applications can range from compact, low power infrared countermeasures to high power, airborne laser systems. IR countermeasure systems use lasers to confuse the seeker heads on infrared homing missiles.

Disorientation

Some weapons simply use a laser to disorient a person. One such weapon is the Thales Green Laser Optical Warner.[19]

Guidance

Laser guidance is a technique of guiding a missile or other projectile or vehicle to a target by means of a laser beam.

Target designator

Another military use of lasers is as a laser target designator. This is a low-power laser pointer used to indicate a target for a precision-guided munition, typically launched from an aircraft. The guided munition adjusts its flight-path to home in to the laser light reflected by the target, enabling a great precision in aiming. The beam of the laser target designator is set to a pulse rate that matches that set on the guided munition to ensure munitions strike their designated targets and do not follow other laser beams which may be in use in the area. The laser designator can be shone onto the target by an aircraft or nearby infantry. Lasers used for this purpose are usually infrared lasers, so the enemy cannot easily detect the guiding laser light.

Firearms

Laser sight

The laser has in most firearms applications been used as a tool to enhance the targeting of other weapon systems. For example, a laser sight is a small, usually visible-light laser placed on a handgun or a rifle and aligned to emit a beam parallel to the barrel. Since a laser beam has low divergence, the laser light appears as a small spot even at long distances; the user places the spot on the desired target and the barrel of the gun is aligned (but not necessarily allowing for bullet drop, windage, distance between the direction of the beam and the axis of the barrel, and the target mobility while the bullet travels).

Most laser sights use a red laser diode. Others use an infrared diode to produce a dot invisible to the naked human eye but detectable with night vision devices. The firearms adaptive target acquisition module LLM01 laser light module combines visible and infrared laser diodes. In the late 1990s, green diode pumped solid state laser (DPSS) laser sights (532 nm) became available. Modern laser sights are small and light enough for attachment to the firearms.

In 2007, LaserMax, a company specializing in manufacturing lasers for military and police firearms, introduced the first mass-production green laser available for small arms.[20] This laser mounts to the underside of a handgun or long arm on the accessory rail. The green laser is supposed to be more visible than the red laser in bright lighting conditions because, for the same wattage, green light appears brighter than red light.

Eye-targeted lasers

A non-lethal laser weapon was developed by the U.S. Air Force to temporarily impair an adversary's ability to fire a weapon or to otherwise threaten enemy forces. This unit illuminates an opponent with harmless low-power laser light and can have the effect of dazzling or disorienting the subject or causing them to flee. Several types of dazzlers are now available, and some have been used in combat.

There remains the possibility of using lasers to blind, since this requires such lower power levels, and is easily achievable in a man-portable unit. However, most nations regard the deliberate permanent blinding of the enemy as forbidden by the rules of war (see Protocol on Blinding Laser Weapons). Although several nations have developed blinding laser weapons, such as China's ZM-87, none of these are believed to have made it past the prototype stage.

In addition to the applications that crossover with military applications, a widely known law enforcement use of lasers is for lidar to measure the speed of vehicles.

Holographic weapon sight

A holographic weapon sight uses a laser diode to illuminate a hologram of a reticle built into a flat glass optical window of the sight. The user looks through the optical window and sees a cross hair reticle image superimposed at a distance on the field of view.[21]

Medical

- Cosmetic surgery (removing tattoos, scars, stretch marks, sunspots, wrinkles, birthmarks, and hairs): see laser hair removal. Laser types used in dermatology include ruby (694 nm), alexandrite (755 nm), pulsed diode array (810 nm), Nd:YAG (1064 nm), Ho:YAG (2090 nm), and Er:YAG (2940 nm).

- Eye surgery and refractive surgery

- Soft tissue surgery: CO2, Er:YAG laser

- Laser scalpel (General surgery, gynecological, urology, laparoscopic)

- Photobiomodulation (i.e. laser therapy)

- "No-Touch" removal of tumors, especially of the brain and spinal cord.

- Intelligent laser speckle classification for skin health assessments (especially regarding damage caused through ageing)

- In dentistry for caries removal, endodontic/periodontic procedures, tooth whitening, and oral surgery

- Cancer treatment

Industrial and commercial

Industrial laser applications can be divided into two categories depending on the power of the laser: material processing and micro-material processing.

In material processing, lasers with average optical power above 1 kilowatt are used mainly for industrial materials processing applications. Beyond this power threshold there are thermal issues related to the optics that separate these lasers from their lower-power counterparts.[22] Laser systems in the 50-300W range are used primarily for pumping, plastic welding and soldering applications. Lasers above 300W are used in brazing, thin metal welding, and sheet metal cutting applications. The required brightness (as measured in by the beam parameter product) is higher for cutting applications than for brazing and thin metal welding.[23] High power applications, such as hardening, cladding, and deep penetrating welding, require multiple kW of optical power, and are used in a broad range of industrial processes.

Micro material processing is a category that includes all laser material processing applications under 1 kilowatt.[24] The use of lasers in Micro Materials Processing has found broad application in the development and manufacturing of screens for smartphones, tablet computers, and LED TVs.[25]

A detailed list of industrial and commercial laser applications includes:

- Laser cutting

- Laser welding

- Laser drilling

- Laser marking

- Laser cladding, a surface engineering process applied to mechanical components for reconditioning, repair work or hardfacing

- Photolithography

- Optical communications over optical fiber or in free space

- Laser peening

- Guidance systems (e.g., ring laser gyroscopes)

- Laser rangefinder / surveying,

- Lidar / pollution monitoring,

- Digital minilabs

- Barcode readers

- Laser engraving of printing plate

- Laser bonding of additive marking materials for decoration and identification,

- Laser pointers

- Laser mice

- Laser accelerometers

- OLED display manufacturing

- Holography

- Bubblegrams

- Optical tweezers

- Writing subtitles onto motion picture films.[26]

- Power beaming, which is a possible solution to transfer energy to the climber of a Space elevator

- 3D laser scanners for accurate 3D measurement

- Laser line levels are used in surveying and construction. Lasers are also used for guidance for aircraft.

- Extensively in both consumer and industrial imaging equipment.

- In laser printers: gas and diode lasers play a key role in manufacturing high resolution printing plates and in image scanning equipment.

- Diode lasers are used as a lightswitch in industry, with a laser beam and a receiver which will switch on or off when the beam is interrupted, and because a laser can keep the light intensity over larger distances than a normal light, and is more precise than a normal light it can be used for product detection in automated production.

- Laser alignment

- Additive manufacturing

- Plastic welding

- Metrology - handheld and robotic laser systems for Aerospace, Automotive and Rail applications

- To store and retrieve data in optical discs, such as CDs and DVDs

- Blueray

Entertainment and recreation

- Laser lighting displays accompany many music concerts

- Laser tag

- Laser harp: a musical instrument were the strings are replaced with laser beams

- As a light source for digital cinema projectors[27]

Surveying and ranging

In surveying and construction, the laser level is affixed to a tripod, leveled and then spun to illuminate a horizontal plane. The laser beam projector employs a rotating head with a mirror for sweeping the laser beam about a vertical axis. If the mirror is not self-leveling, it is provided with visually readable level vials and manually adjustable screws for orienting the projector. A staff carried by the operator is equipped with a movable sensor, which can detect the laser beam and gives a signal when the sensor is in line with the beam (usually an audible beep). The position of the sensor on the graduated staff allows comparison of elevations between different points on the terrain.

A tower-mounted laser level is used in combination with a sensor on a wheel tractor-scraper in the process of land laser leveling to bring land (for example, an agricultural field) to near-flatness with a slight grade for drainage. The laser line level was invented in 1996 by Steve J. Orosz, Jr.[1] This type of level does not require a heavy motor to create the illusion of a line from a dot, rather, it uses a lens to transform the dot into a line.

Bird deterrent

Laser beams are used to disperse birds from agricultural land, industrial sites, rooftops and from airport runways. Birds tend to perceive the laser beam as a physical stick. By moving the laser beam towards the birds, they get scared and fly away. On the market are manual operated laser torches[28] or automated robots[29] to move the laser beam automatically.

Images

-

The surface of a test target is instantly vaporized and bursts into flame upon irradiation by a high power continuous wave carbon dioxide laser emitting tens of kilowatts of far infraredlight. Note the operator is standing behind sheets of plexiglas, which is opaque in the far infrared.

Applications:

3D

Engraving

Stage Lighting